Savonia Article Pro: Microbes as the foundation of the circular economy and security of supply

Savonia Article Pro is a collection of multidisciplinary Savonia expertise on various topics.

This work is licensed under CC BY-SA 4.0

Adjunct Professor Elias Hakalehto (University of Helsinki, University of Eastern Finland, Finnoflag Oy) visited Savonia University of Applied Sciences in April 2024 to lecture mechanical engineering students. The main focus was an introduction to the principles of a microbiological biorefinery. This is related to many topics in the Environmental Management of Production Enterprises course, such as the circulation of substances in nature, the circular economy, and renewable energy sources such as biogas, hydrogen, and biofuels for transportation.

Here are two additional questions for Elias:

• How can biotechnology and equipment design be used to improve security of supply?

• What is holistic circular economy in industry?

Elias began the lecture by asking what is the difference between microbes, bacteria, and viruses. He explained that he has found it fascinating to study the ubiquitous microorganisms throughout his career. These organisms are not visible to the naked eye due to their small size, but their impact is clearly evident. Despite their small size, microbes play a crucial role in the functioning of the world, as they are key players in the natural nutrient cycles and food chains. Microbes also have a significant role in the functioning of the human body. Only a tiny fraction of microbes are harmful, and many can be utilized beneficially.

Alongside effectively identifying microbes and promoting hygiene, Elias has always aimed to advance the use of microbes to produce valuable commodities, such as biochemicals for the food and pharmaceutical industries, recycling industries, organic fertilizers for agriculture, energy gases and fractions, polymers, and various services like environmental cleanup and the production of food or feed. Additionally, the production of enzymes and fine chemicals is set to become increasingly significant in the future. These numerous production lines can be established during crises to replace and supplement other forms of production.

In holistic circular economy thinking, side streams can be entirely converted into useful chemicals, energy gases, and organic soil conditioners. This significantly increases the range and availability of raw materials for the industry and improves the security of supply for the entire national economy. For example, during the First World War, Winston Churchill harnessed whisky distilleries in England to produce essential industrial chemicals using microbes.

Elias explained that various fermentation processes have long been a means for humans to produce food. In the food industry, there are many microbiological processes, such as the production of yogurt, sour milk, blue cheeses, and fermented vegetables.

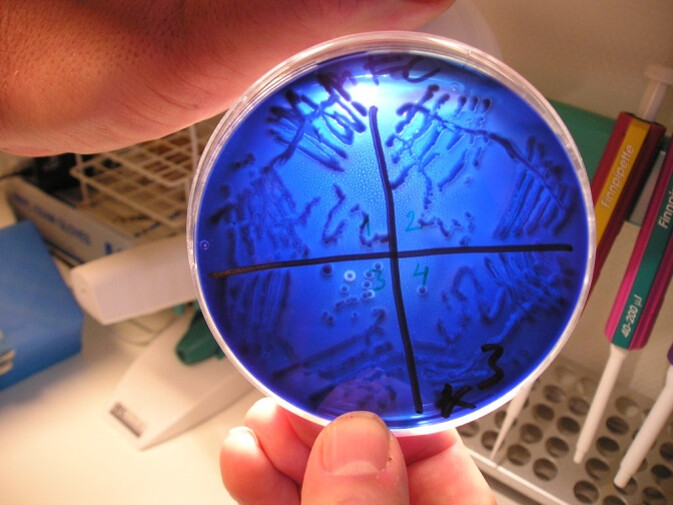

Microbes have also been used to produce many medicines. Elias shared an interesting story about the discovery of antibiotics, starting in 1929 when Alexander Fleming was studying staphylococci bacteria in London, and a mold spore landed on a Petri dish. Fleming noticed that this mold produced a substance that destroyed the bacteria. This led to the discovery of penicillin. In 1942, two British researchers traveled to America to find funding for penicillin production. Penicillin began to be produced industrially, and it is estimated that the lives of two million soldiers were saved from wound infections on the battlefield during WW2 already. Subsequently, other antibiotics were researched and discovered.

Lessons can be learned from nature’s economy for human economy

Elias studied at three universities in England in the 1980s, one of which was University College London. There, he had the opportunity to hear lectures from veterans (such as Professors Malcolm D. Lilly and Peter Dunnill) who had been involved in the first antibiotic research. For his thesis at the current Westminster University, Elias performed the world’s first transfer of an antibiotic gene (gene for clavulanic acid) from Streptomyces sp. strains to E. coli in 1985. In a big picture streptomycetes produced then 95% of different clinically used antibiotics.

Taking many examples from nature, Elias illustrated to students how lessons can be learned from natural economy for human economy. He described how ruminants have a wide range of microbes in their rumen that can turn, for example, hay into products that the ruminant can use. He used the American bison as an example, which eats dry hay on the prairie and develops a ton-sized body with a lot of muscle, bones, hide, manure etc. This is possible because the rumen microbes are functioning well. Ruminating is an efficient decomposition process, allowing the bison to obtain the necessary substances for its growth and bodily functions from the hay. We can take a cue from ruminants on how to break down food macromolecules first with enzymes, and then microbes can use them as raw materials to produce various products more quickly. The bisons and their microbes are also providing the nutrients for plant growth for the hay, and thus the circulation in their prairie ecosystem, and the same is true with other ruminants in their own ecosystems or environment.

Nature’s examples and microbiology offer many opportunities for developing high technology and applying technology in practice. The starting point is the invisible microbes and their enzymes. To utilize these, mechanical engineering equipment is needed to harness the phenomena. A bioreactor can be, for example, a stirred tank, a basin, or an air-lift type reactor. Elias emphasized the need to integrate biology and technology. Microbial metabolism is rapid; with favorable conditions, their reactions occur swiftly.

A bioreactor must have good conditions for microbial growth and production activity: temperature, pH, redox potential, energy source, and sources of carbon, nitrogen, phosphorus, and sulfur. Additionally, other minerals, trace elements, and vitamins must be available. Temperature ranges and optima depend on the type of microbe.

In Finnoflag’s concepts, the processes are based on the natural microbes of the feedstock and the addition of industrial microbial strains. This creates a mixed culture, a diverse ecosystem that produces desired products with high productivity. Elias explained to the students how microbes work together and form a network of various interactions, where their activities aim for a balance that benefits the whole, leading to maximum product formation under scientific and technical guidance. Microbial communities are versatile and have competences for different situations.

The biocatalytic potential of microbes can be utilized in industry

Elias mentioned that when producing products through their metabolism with enzymes, microbes require only a fraction of the catalytic reaction energy needed for producing the same substances through chemical synthesis. Bioprocess technology allows the production of a wide variety of chemical products, even more diverse than what is possible with chemical processes. The biocatalytic potential of microbes can be utilized in many ways in the industry, such as in the production of biogas and biological hydrogen (biohydrogen).

For instance, in the ABOWE pilot project, funded by the EU’s Baltic Sea Region Programme and led by Savonia, a new type of biorefinery pilot plant was designed and built, which was tested in Finland, Poland, and Sweden. Finnoflag Oy, as a Key Technology Provider, brought microbiological and biotechnical expertise to the project, which included partners from Germany, Estonia, and Lithuania. ABOWE was also funded by the Ministry of Employment and the Economy, among others.

Based on the results of ABOWE’s trial runs at Savon Sellu’s corrugated cardboard factory in Kuopio (now Mondi), there is significant potential for the production of hydrogen and other valuable products from future wastewater and sludge generated at wastewater treatment plants.

In ABOWE’s Swedish trials, it was found, for example, that when waste processed in the biorefinery pilot plant was fed into biogas production, this feedstock gave the best biogas yield compared to raw wastes that were not processed in the biorefinery pilot plant.

The products of biorefining in Finnoflag-led pilot projects have included:

• Lactic acid from milk sugar (lactose), or as a degradation product of macromolecules

• Energy gases, such as hydrogen,

• Biofuels, such as ethanol and butanol,

• Platform chemicals, such as raw materials for producing plastic, synthetic rubber, cosmetics, and textiles, for example 2,3-butanediol,

• Pharmaceutical substances, such as excipients (carriers), for example, mannitol,

• Organic soil conditioners,

• The remediation of contaminated soils and waters.

Mannitol is a common additive in xylitol chewing gum and is increasingly used as an excipient in medicines. For instance, the international pharmaceutical giant Merck has anticipated mannitol to be an important carrier substance in the future. Additionally, Biobased is an emerging trend in many fields worldwide.

The scale of the biorefinery process needs to be gradually increased; it is not possible to move directly from the laboratory to full-scale production. Scaling involves many considerations that must be taken into account. Based on Elias’s experience, a suitable progression is, for example, that the next scale is 10 times larger than the previous level.

Applying the modern Industry 4.0 concept, biotechnological expertise could be based in Finland, from where biotechnological production facilities around the world could be remotely controlled.

There is a lot of cellulose-containing waste in Finland. For example, in Hiedanranta of the city of Tampere, there is at least 1.5 million cubic meters of fiber sludge at the bottom of the lake, dumped by a wood processing plant that operated in the area until the 1960s. Zero fiber was used as a raw material for biorefining in extensive and long-term studies funded by the city of Tampere and the Ministry of Agriculture and Forestry. The main products of the biorefining trials were lactate and mannitol. Zero fiber does not contain microplastics, so the material after biorefining would be suitable as fertilizer. As noted in the ABOWE trials, its quality improves in terms of plant nutrient availability. Its nitrogen content can also be increased by nitrogen-fixing bacteria. Finnoflag has achieved good greenhouse trial results for nitrogen fixation at the University of Helsinki’s Viikki campus. Adding one nitrogen-fixing bacterial strain to the cultivation of Chinese cabbage resulted in 50% greater growth in two months.

Zero fiber would have significant monetary value. In Hiedanranta studies, Elias’s calculations provided a rough estimate that biorefining as proposed by Finnoflag Oy would be €500 cheaper per Tampere resident compared to directly burning the valuable raw material.

Sustainable industry could be built on the basis of natural economy. Finnoflag Oy holds a globally registered trademark, Industry Like Nature®, meaning industry in the way of nature. Microbes and understanding them play a central role in this.

Author:

Senior Lecturer Ari Jääskeläinen, M.Sc. (Tech.), B.Soc.Sc.

Savonia University of Applied Sciences